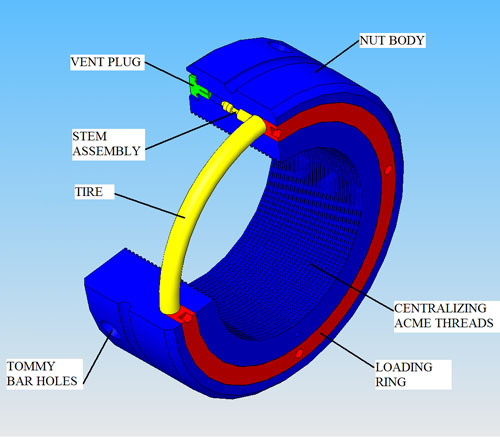

The Pilgrim Nut, designed in the early 1960’s by Pilgrim Engineering, was introduced to the U.S. in 1966 by Mapeco Products. It quickly became the industry standard for fitting propellers, rudder stocks and pintles, and tapered shaft couplings.

The Pilgrim Nut is screwed onto the shaft until the loading ring is tight against the face of the propeller, coupling, or rudder casting. Hydraulic pressure from an air/hydraulic intensifier inflates a hollow tire, generating a high and closely controlled axial load up to 5000 tons. The applied load pushes the propeller or coupling onto the shaft taper, or the rudder or steering gear casting onto the rudder stock or pintle taper, and allows the Pilgrim Nut loading ring to move out of the body. This axial force can also be used for preloading bolts, studs, or shafts. When preloading fasteners, shims or a threaded locking ring are used to retain the applied load.

The Pilgrim Nut is screwed onto the shaft until the loading ring is tight against the face of the propeller, coupling, or rudder casting. Hydraulic pressure from an air/hydraulic intensifier inflates a hollow tire, generating a high and closely controlled axial load up to 5000 tons. The applied load pushes the propeller or coupling onto the shaft taper, or the rudder or steering gear casting onto the rudder stock or pintle taper, and allows the Pilgrim Nut loading ring to move out of the body. This axial force can also be used for preloading bolts, studs, or shafts. When preloading fasteners, shims or a threaded locking ring are used to retain the applied load.

The primary advantage is the simplicity of operation and in the precision of the applied loads. Pre-determined installation and removal calculations are provided for a guaranteed fit.

Applications:

- Propellers

- Rudder Stocks & Pintles

- Tapered Shaft Couplings

Benefits Include:

- No torsional stresses

- Galling and seizing eliminated

- No heat required

- High residual loads

- Precise & repeatable loading

- Easy operation

- Approved by all major classification societies

Applications

Inspection of Pilgrim Nut threads using an Optical Comparator

Inspection of Pilgrim Nut threads using an Optical ComparatorPropellers

The goal with any tapered assembly is to achieve an interference fit between the tapered surfaces which will prevent rotational movement or separation of the surfaces under all operating conditions. Pilgrim Nuts provide enough force to achieve this fit.

Mapeco calculates the required advance up the taper. By using a hydraulic pressure gauge and a dial indicator, the advance can be accurately measured and matched to the pre-determined requirements, resulting in precise and repeatable loading.

The nuts can be provided with centralizing ACME threads or plain bored.

Rudder Stocks and Pintles

Loose rudder connections and cracked rudder stocks can be eliminated by providing sufficient friction grip to prevent rotation between the rudder stock and rudder, or steering gear. Additionally, separation between the rudder stock and a spade rudder or between a pintle and its gudgeon is eliminated by providing an adequate interference fit.

Pilgrim Nut on top end of rudder stock

Pilgrim Nut on top end of rudder stock Tapered Shaft Couplings

Keyed tapered shaft couplings may be installed or removed utilizing the same procedure as used with propellers.