Mapeco Hydraulic Bolts

Mapeco hydraulically actuated bolts are designed to provide fast, cost-effective and trouble-free installation and removal. By eliminating the need for hammering conventional bolts into holes, which often cause scoring of both the hole and bolt surface, our bolts can be repeatedly installed and removed quickly without damage to either the bolt or the hole.

Unlike bolts that are tensioned using small screws in a circle, Mapeco hydraulically tensioned bolts have no risk of a bending moment being applied, so there is no bending stress added to the axial stress after installation.

Pilgrim Radial Fit Bolt

Approved by all major classification societies, the primary application of the Pilgrim Radial Fit Bolt is to connect the propulsion shaft equipment and shaft sections at the face to face coupling flange. When the tapered bolt is hydraulically drawn into the tapered sleeve, the sleeve is forced to expand inside the hole forming a pre-engineered interference/pressure fit. The bolt is then hydraulically tensioned to provide a pre-determined secure clamping force across the flanges. Removal is achieved by relieving the clamping force and using oil-injection to separate the bolt and sleeve. The most important factor is that when the sleeve and bolt are separated, the sleeve returns to its original clearance condition, allowing easy removal of both the bolt and sleeve.

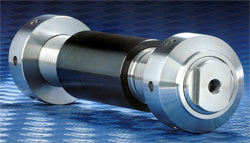

Morgrip Bolt

Working on the principle that the bolt diameter will reduce when stretched within its elastic limit in accordance with Poisson’s Ratio, the Morgrip Bolt is extremely versatile and can be used in a variety of conditions and applications. This simple concept allows the bolt to be applied as a fitted bolt utilizing both radial and axial loading, as a dowel to utilize its radial load characteristics, and as clamping bolts with axial loading only. Typical applications include rudder assemblies, propulsion shaft couplings, CP propellers, and flange mounting propellers.

The Morgrip Bolt’s elasticity allows quick and easy hand fitting and removal without damage to either the bolt hole or the bolt itself, thus eliminating the problems of bolt seizure and hole re-machining associated with conventional sold fitted bolts. For shaft couplings with low length to diameter ratios, the Morgrip Bolt is stronger than radial fit bolts.

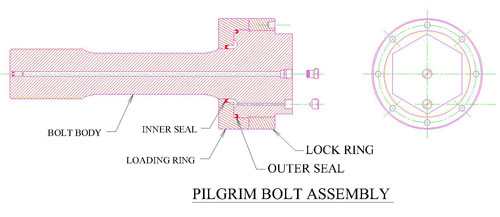

Pilgrim Bolt

Pilgrim Bolts utilize a hydraulic jacking feature in the bolt head to stretch the bolt, which is retained using shims or a threaded locking ring. Providing an axial grip only, these bolts retain a higher percentage of the axial load after the hydraulic pressure is released. These bolts are most often used for ships hull structural and machinery fastening.